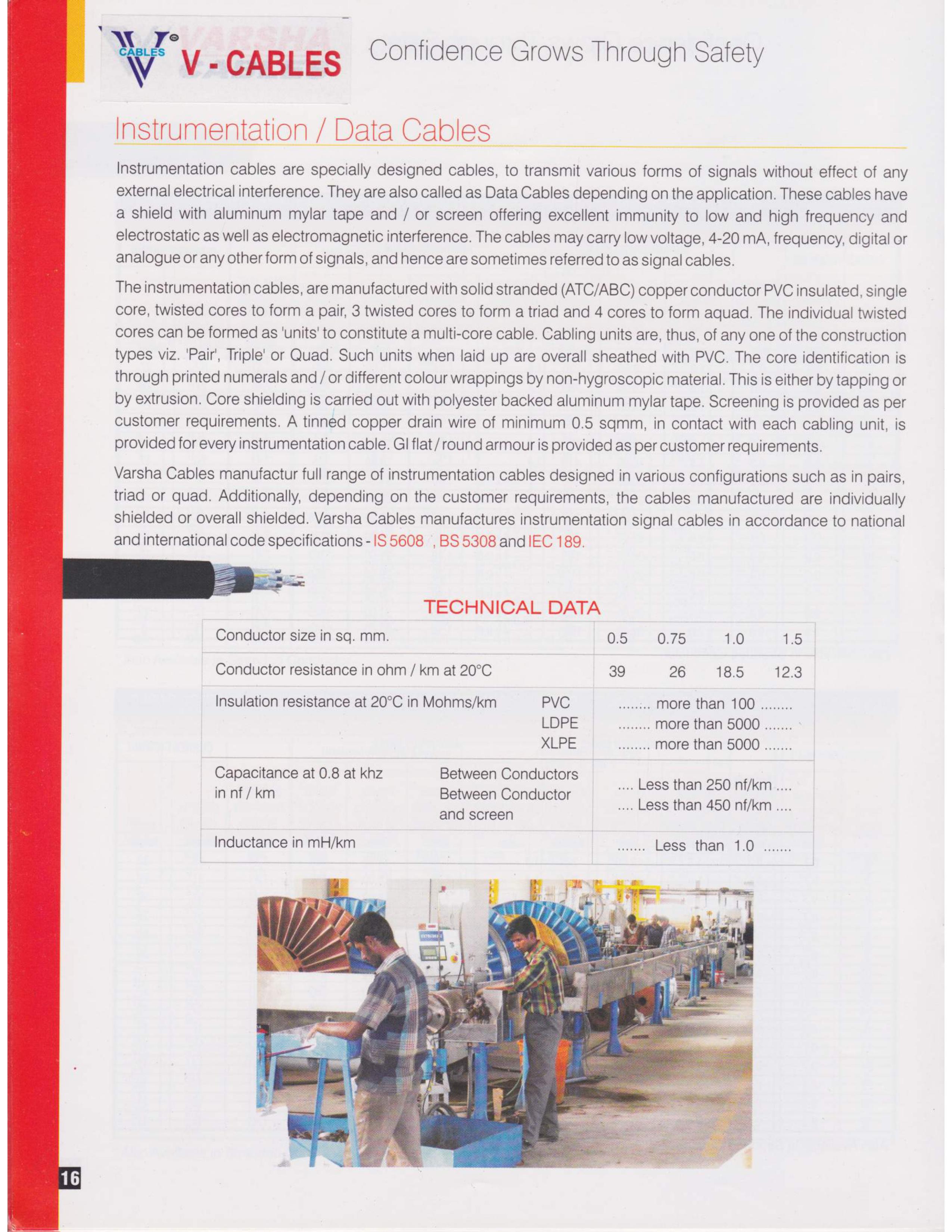

VCables Process

Varsha cables have ISO 9001:2000 certified manufacturing and quality testing procedures. The cable manufacturing at Varsha cables is carried out as follows:

CONDUCTOR:

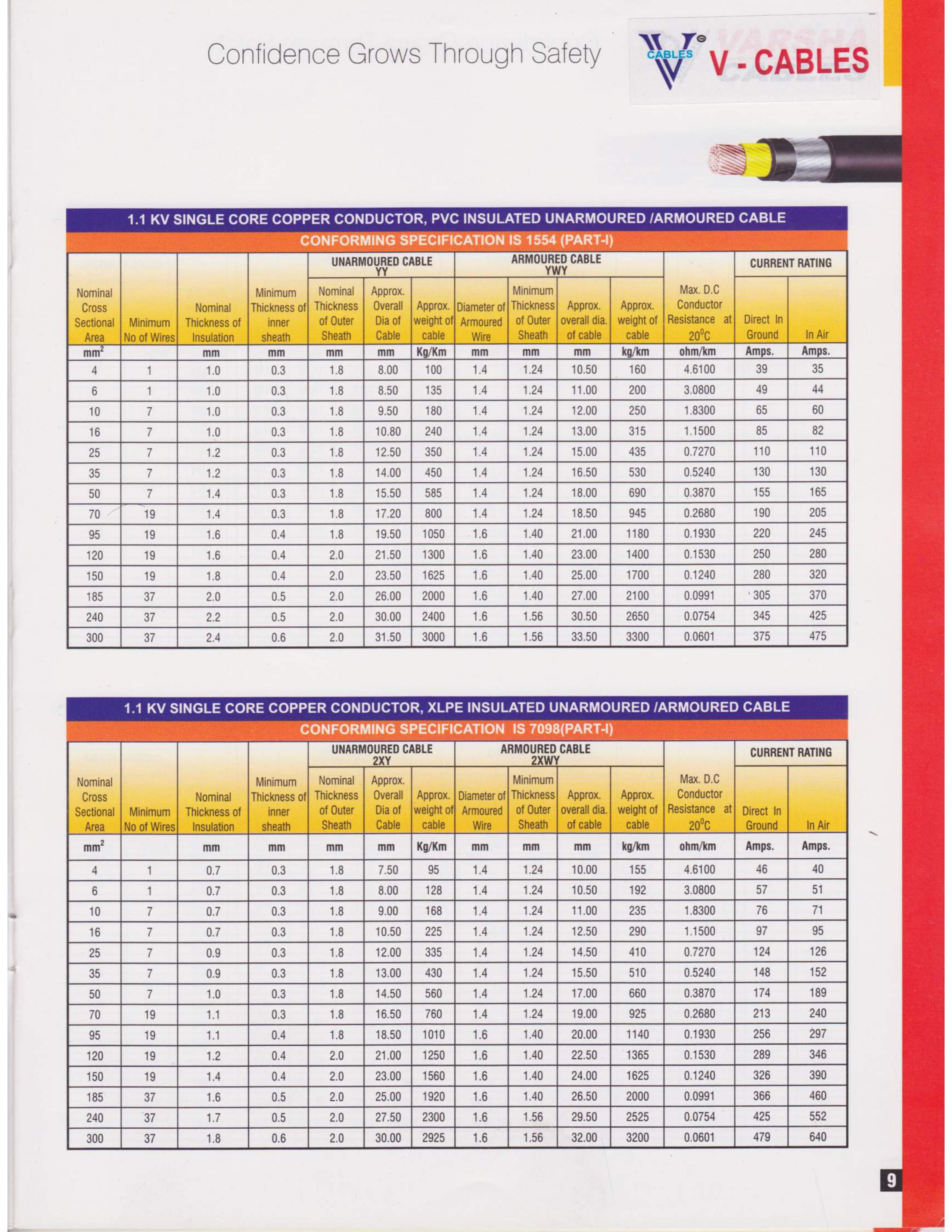

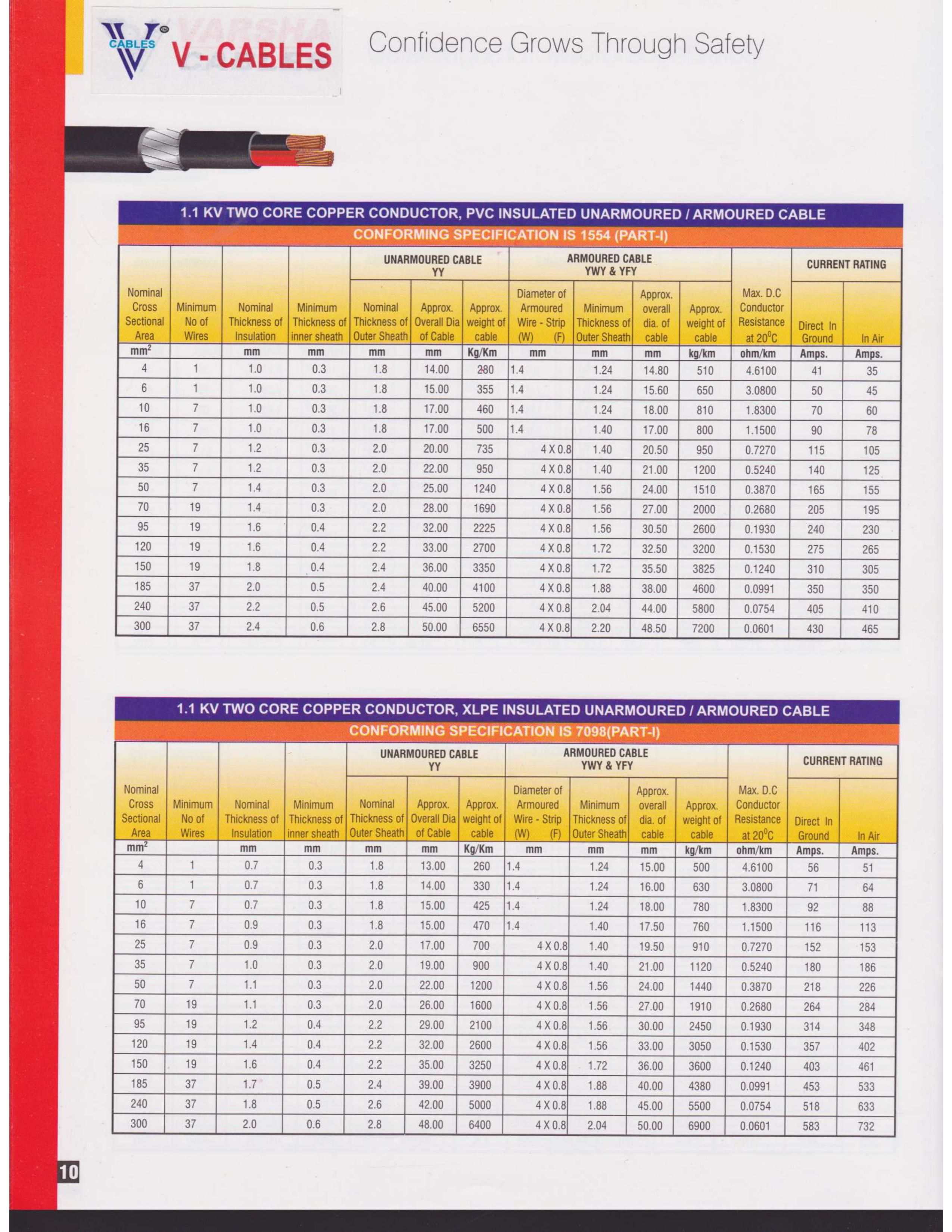

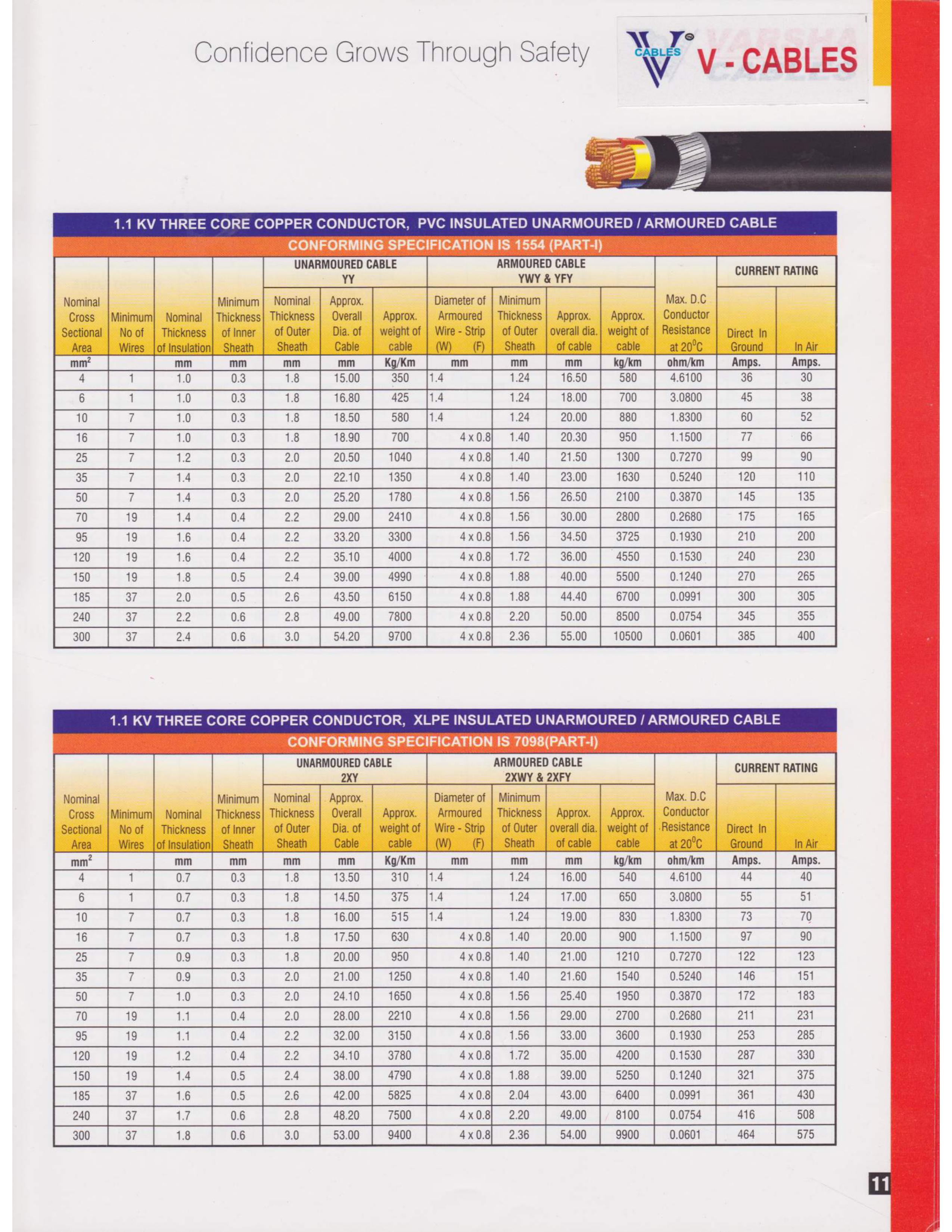

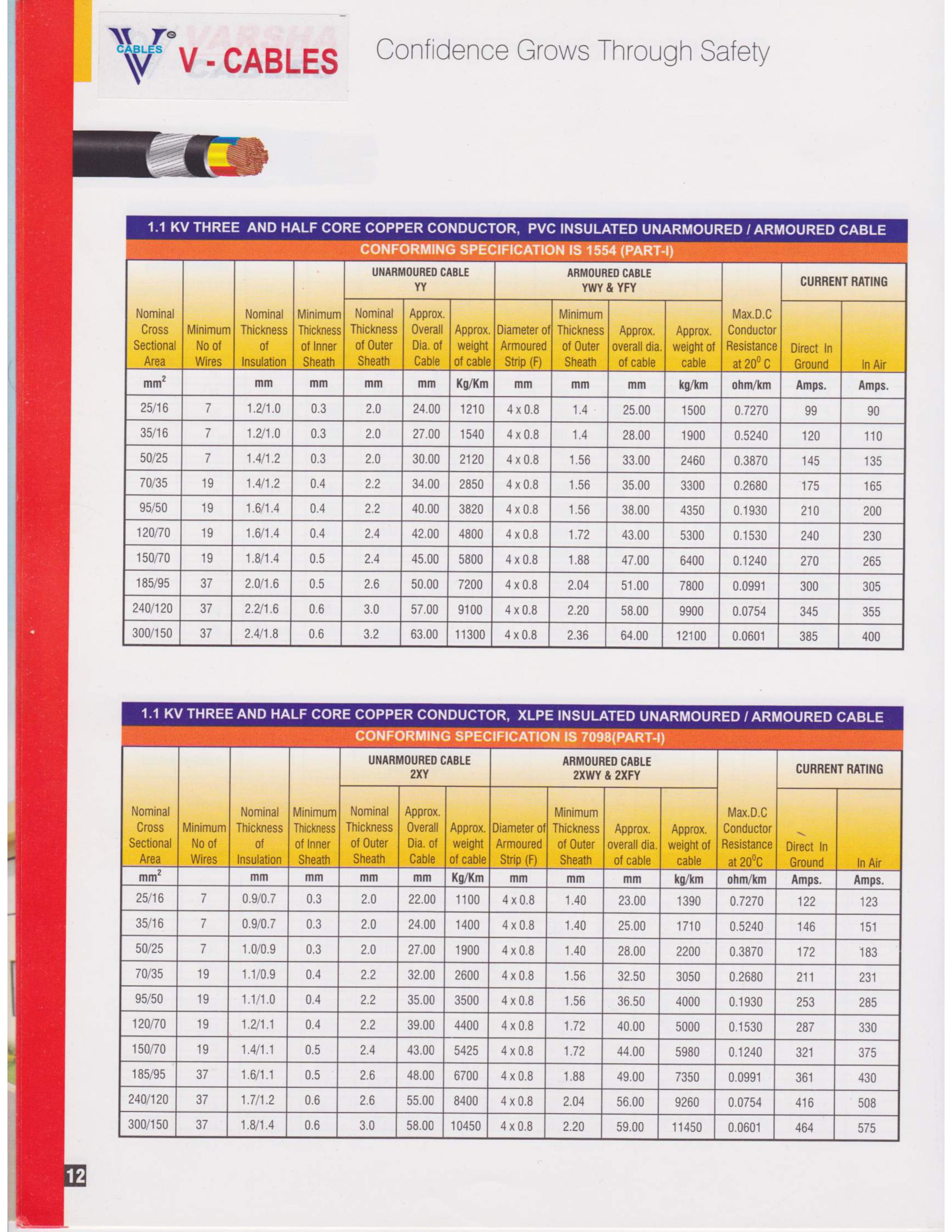

Conductors are drawn from bright electrolytic grade high conductivity copper (and annealed) and H2 / H4 grade aluminum. After drawing various sizes, conductors are formed in various configurations such as solid, stranded, circular or shaped. All conductors at Varsha cables are manufactured in accordance with national and international codes / specifications IS 8130, IEC 60228 and BS 6360.INSULATION:

The conductors are insulated with high quality PVC/XLPE compound having high insulation resistance. the insulation process is carried out on modern high speed extrusion lines giving improved reliability and compactness to cables with higher accuracy ensuring consistency in performance on field. The XLPE extruded cores are cured at specified temperature requirements. Insulation at Varsha cables is carried out in accordance with national and international codes / specifications IS 5831, IS 7098, BS 6746, BS 5467 and IEC 60502.COLOUR IDENTIFICATION:

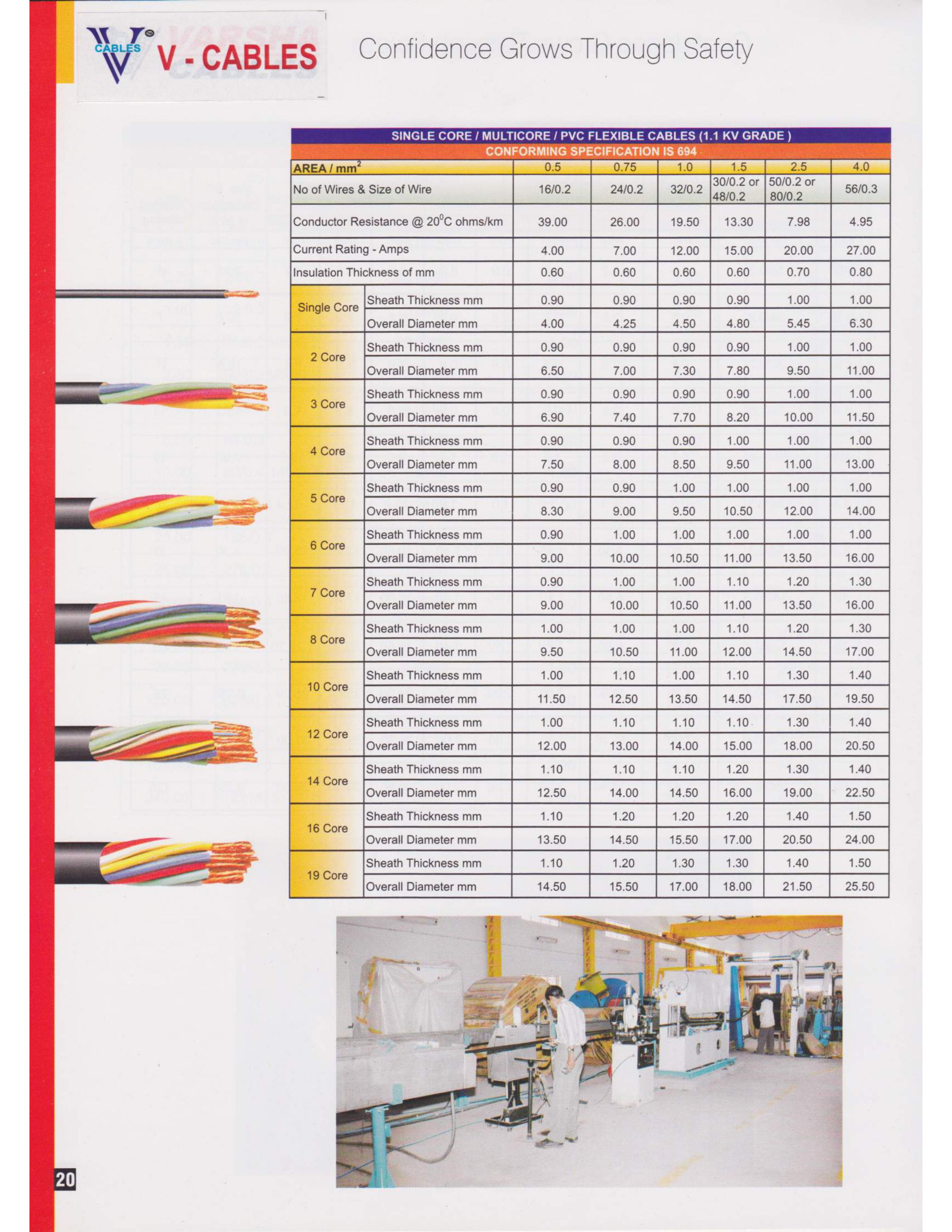

Colour identification is of utmost importance, especially for the control cables. Different cores in the cables are identified by different colors. At Varsha cables, the following color scheme is adopted unless specifically called for,- Single core RED, YELLOW, BLUE or BLACK

- 2 core RED and BLACK

- 3 core RED, YELLOW and BLUE

- 4 core RED, YELLOW, BLUE and BLACK

- 5 core RED, YELLOW, BLUE, BLACK and LIGHT GREY